INNOVATION

Rideout Arsenal designed the Dragon from the ground up to be the fastest follow up shot competition pistol on the market. We've done this by addressing the primary delay between shots, reaquiring a sight picture. All traditional hand guns place the barrel bore axis well above the shooters hand. This results in muzzle flip as recoil forces impart a twisting torque on shooters grip. The shooter then needs to push the barrel back down on target and line up the sight on target. Moving the bore inline with the web of the shooters hand essentially eliminates recoil induced muzzle rise. The smooth operating lever delayed blowback operating system gently applies recoil forces to the shooter resulting in a very flat and controllable shooting experience.

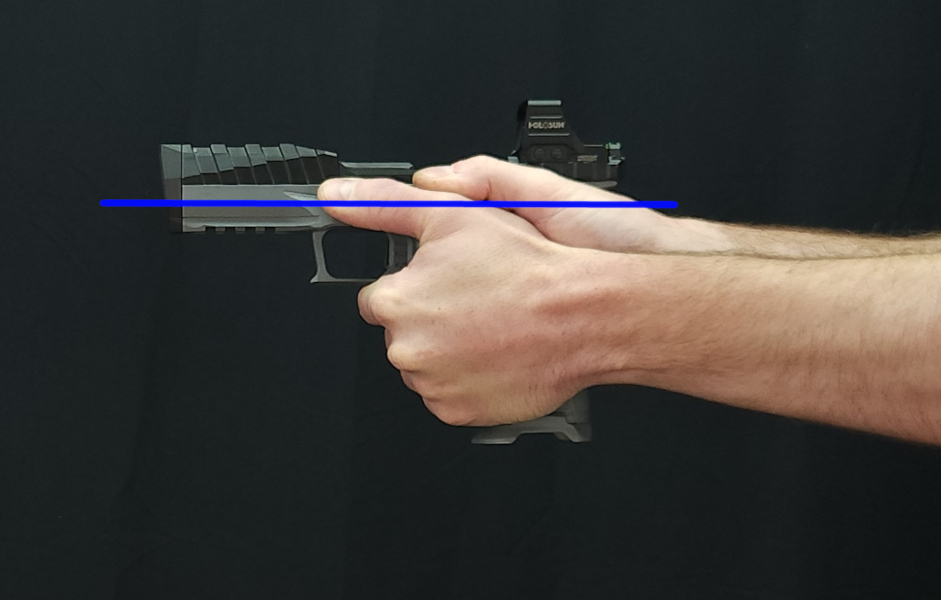

BORE AXIS

The Dragon features an industry leading low bore axis. Aligning the barrel inline with the shooters grip drastically reduces recoil induced muzzle rise. Minimal muzzle rise means extremely fast followup shots. This innovative configuration produces an astoundingly flat shooting pistol without the use of ports or compensators.

BORE TO GRIP

The barrel bore axis sits very low in the shooters grip.

GRIP ERGONOMICS

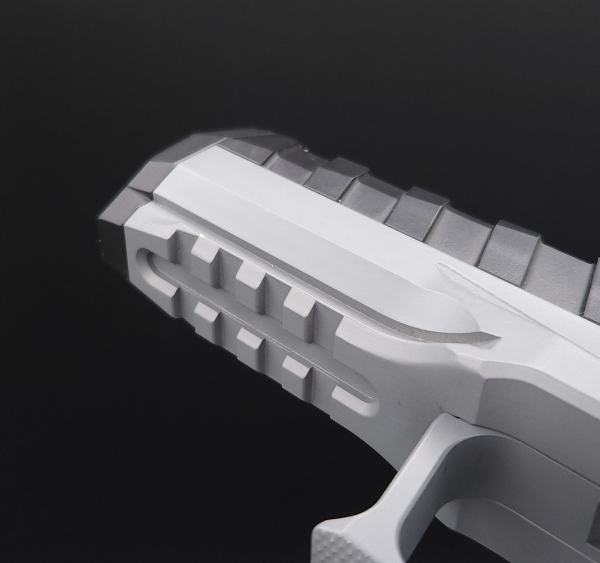

The ergonomic backstrap has a prominent hump that aids the shooters in getting a high purchase. The large flat "beavertail" under the N-ROC gives a comfortable and fast to acquire grip.

FIXED BARREL

Inherent accuracy without the need for custom hand fitted tight tolerance moving parts. Non-moving barrel enables extremely low bore axis.

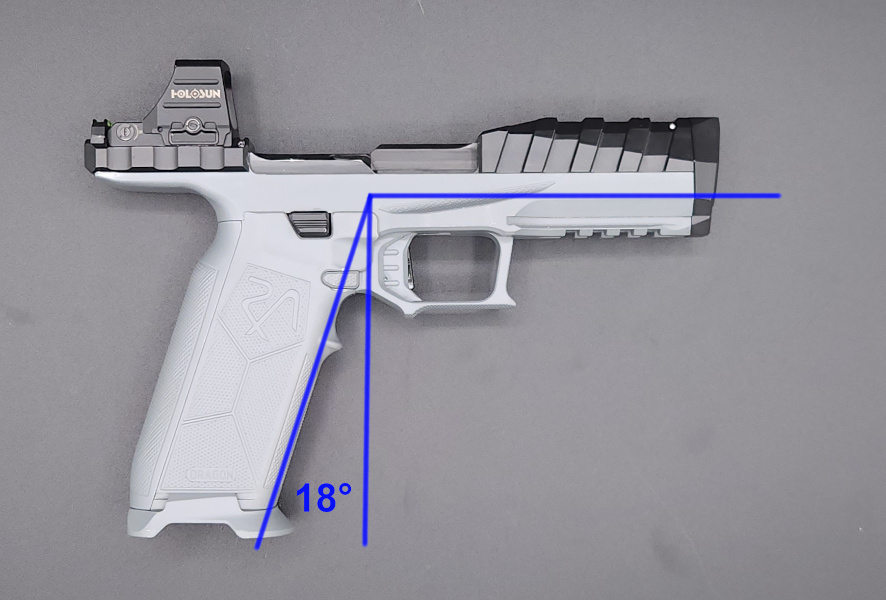

GRIP ANGLE

The grip features a familiar 18° angle.

LEVER DELAYED BLOWBACK OPERATING SYSTEM

The Dragon uses an innovative patent pending forward mounted lever delayed blowback operating system.

A lever mounted at the front of the bolt interfaces with the bolt carrier. When a cartridge is fired, the expanding gas pushes against the bolt face, initiating rearward movement. However, the lever's geometry and placement creates a mechanical disadvantage that delays the bolt's rearward travel. The lever pivots and transfers the force to the bolt carrier, effectively multiplying the apparent weight of the bolt. This delay allows the pressure in the barrel to drop to a safe level before the bolt unlocks and cycles. Once the pressure drops, the bolt and bolt carrier move together rearward, ejecting the spent case and loading a new round.

SMOOTH RECOIL IMPULSE

The Lever linkage ratio between the Bolt and Bolt Carrier results in a very smooth opening action of the breach. The resulting feel is gradual application of the recoil force, not a snappy kick.

DEEP FULL WRAP SERRATIONS

The Bolt Carrier takes the place of a traditional slide. It features deep cut fully wrapped serrations providing excellent grip to operate the action.

GAS-LESS

Purely mechanical operation runs cool and stay clean much longer than gas delayed systems. It is also not prone to lead fouling meaning the Dragon is not ammo particular.

ROBUST AND SERVICABLE

All of the components of the lever delay system are made from S7 shock resistant tool steel. This results in a long lasting reliable operating system. When service is required, the 3 small components are easily replaced.

MODULAR

The Dragon was designed with modularity as a key requirement. This modular system allows for extensive user configuration as the product suite expands. The N-ROC, Grip module, Backstrap, Mag Funnel, and Nose can all be quickly and tool-lessly swapped out. The Fire Control Group is a totally self contained module built into the Trigger Guard. The modular subsystems of the Dragon include several patent pending innovations.

FIRE CONTROL GROUP

The Fire Control Group houses the "energized component" (Sear). The Dragon FCG is classified by the ATF as the "firearm", and is marked and serialized.

GRIP, BACKSTRAP, AND MAG FUNNEL

The grip module, backstrap, and mag funnel can all be quickly and tool-lessly swapped. Future accessory offerings will include a range of grip and backstrap sizes and texture patterns. The Dragon can be operated with the competition mag funnel installed or removed.

QUICK DETACH NOSE

The nose directly attatches to the fixed barrel via a quick detatch tri-lug interface. This allows rapid and tool-less swaps to accomadate accessories such as silencers, front sight variants, and tunable weight modules.

CHASSIS

The 7075-T651 Chassis incorporates "gas pedal" thumb rests on both sides for identical handling with strong hand and weak hand operation.

SIGHTS

The N-ROC (Non-Reciprocating Optics Carrier) is a core feature, and patent pending innovation, of the Dragon pistol. The N-ROC serves as a rock solid mounting platform for the RMR footprint optic. During operation the N-ROC stays firmly fixed to the chassis, via its auto locking detent, keeping the sight picture stable. Yet, the shooter can still use the optic to charge the bolt. This allows users can quickly put the Dragon in to service without re-training from traditional slide mounted optics.

OPTIC CUT FOOT PRINT

Incorporating the most popular optic footprint, RMR. Future accessory offerings will include additional industry optic footprints as well as a "iron" only fully adjustable rear sights.

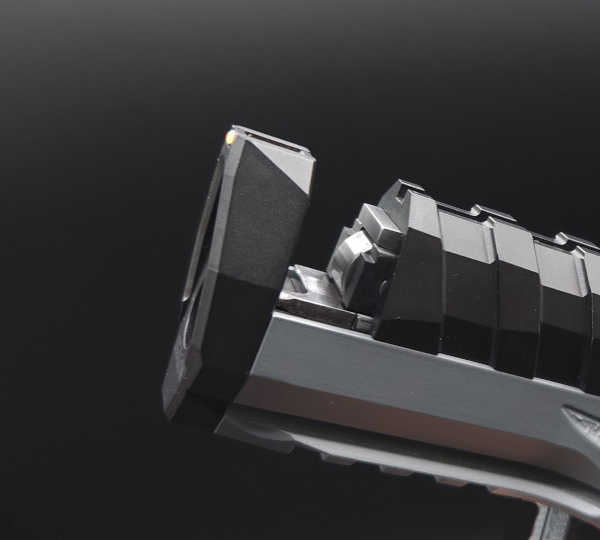

IRONS

Back up co-witnessed (1/4 height) fiber optic sights are built into the Dragon. The front sight is mounted into the nose and stays fixed during shooting. The windage adjustable rear sight is mounted behind the optic on the N-ROC providing an extremely solid sight picture.

TRUE ZERO INTERFACE

Large and wide spread railed interface ensures solid optic mounting and perfect return to zero when removing and re-installing the N-ROC. This allows quickly swapping out optics without the need to re-zero.

AUTO LOCKING

The N-ROC automatically locks to the chassis during firing, preventing the optic from moving. No special hand placement or buttons need to be pressed to use the N-ROC to cycle the bolt. This intuitive operation doesn't require re-training to effectivly put into action.

FEATURE PACKED

Integrated recoil buffer

Single finger swell front strap

"Speed Rack" flush front sight

Picatinny rail

Highly textured grip

Wide shelf Bolt Release

Deep trigger under cut

True ambidextrous controls

Trigger Safety